Logistics companies have played a major role in supporting society throughout the coronavirus lockdown. Delivery firms are now a lifeline for the economy, ensuring that goods get to people who need them most.

However, as vital as delivery firms have been, there have been several occasions when the sheer demand for their services has left customers disappointed. For instance, Ocado, the fastest-growing eGrocery in the UK, saw their website crash and customers reported that they were having to wait in queues of up to 2,000 people just to place their orders. Meanwhile eCommerce stores like Amazon, which promise one day deliveries, have seen delays as long as one month during the current lockdown.

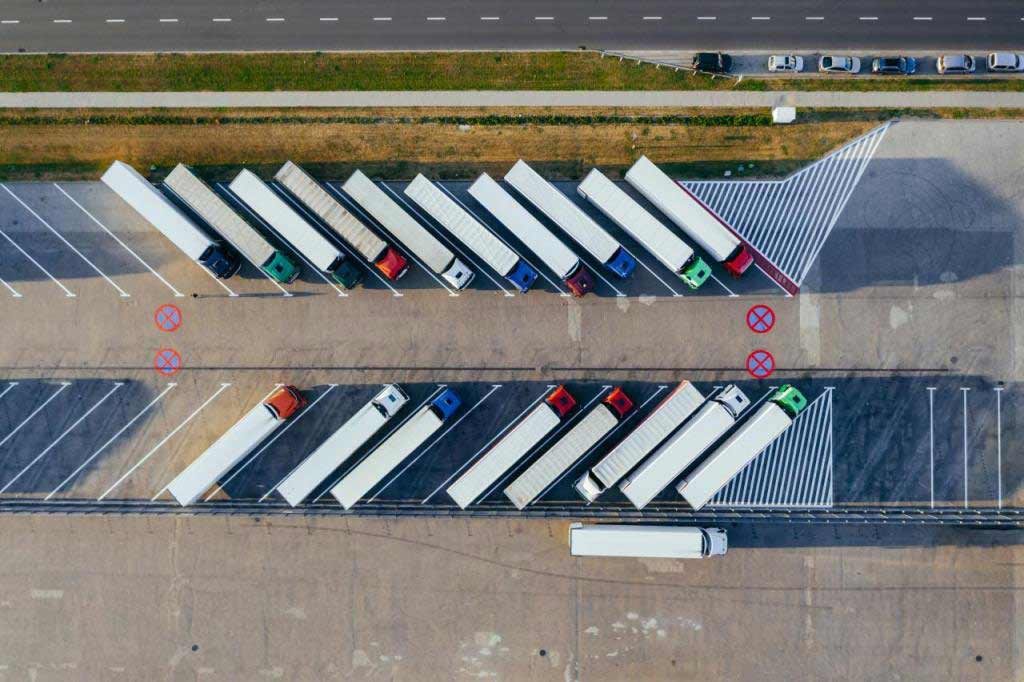

One of the main reasons that eCommerce operations have stumbled during the crisis is because of physical constraints in fulfilment centres and warehouse parking design. Warehouses are a crucial link in the supply chain, as they organise goods from suppliers before sending them to customers. However, warehouses are finely tuned operations, so a sudden jump in demand can create severe disruption. And, one of the major causes of bottlenecks is layout design and vehicle management at depots, warehouses and fulfilment centres. The increase of traffic through their estates has added further stress to a system already under pressure. However, solutions are available. By using smart parking systems as part of warehouse automation, delivery companies can adapt to this fast-changing situation.

A new delivery landscape

The coronavirus has changed the logistics and deliveries landscape forever.

The lockdown has changed the delivery business in several ways:

- Dramatic rise in online purchases in a small space of time

- Different kinds of goods being purchased to usual (i.e. rise in food, medicine and books, while fashion has suffered)

- Different profile of customer – more elderly shoppers with different product and delivery needs

- Spike in specific types of delivery – especially food purchases – amidst rising stocks of unclaimed goods which phase out capacities

New habits

In the first week of April, online retail sales rose by 22% compared to 2019 – for delivery drivers, this is like asking them to do an extra day of work each week! The coronavirus is a ‘black swan’ moment – no delivery or logistics company could have predicted it. Nevertheless, it has exposed weaknesses in the way the industry organises logistics, and it will be essential to adapt. Because, even once the pandemic has passed, consumers will have got into the habit of shopping online more often, so demand will likely remain high in the long term.

And getting logistics ‘right’ is incredibly important. One study during the Christmas season (which sees equivalent demand to the coronavirus pandemic) showed that delivery issues were costing companies $1.5 billion in lost revenue. The companies which can avoid delays and provide the best delivery experience will benefit long term.

Warehouse layout design: a pinch point

Many companies have proven very capable of reorganising warehouses and processes to ensure the right products are available for delivery during lockdown. However, they have not been able to overcome one of the largest causes of delay: vehicle management within their estates.

Unlike other process and workflow problems, this is not something that can easily be designed out. Warehouses and fulfilment centres have limited access to space; there are a set number of packing bays available and a limited number of vans, trucks and lorries which can physically enter the estate. In ‘normal’ times, when demand is not so high, it has been perfectly possible to smoothly process vehicles through fulfilment centres. However, these are not normal times.

When it comes to managing vehicles on their estates, warehouses, depots and fulfilment centres are encountering several concurrent problems which are causing serious delays and disruption:

Sheer increase in traffic

With more delivery vans, lorries and trucks passing through fulfilment centres than ever before, queues are building up on and off site. This results in confusion, dock area congestion and delays – drivers do not know where to park, while idling vehicles block entry and exit routes.

New packing procedures

When vans, lorries and trucks eventually reach packing bays, they are spending more time than usual because of coronavirus-related challenges. For instance, supermarkets are using more plastic bags to pack items and organising delivery boxes differently. This increases the time spent loading boxes and deciding how to place them in the van.

New, inexperienced drivers

The coronavirus has led to a spike in hiring for delivery drivers. Many are relatively inexperienced, especially when it comes to eCommerce delivery. This will, in the short term, result in mistakes and delays in driving on your estate.

Overcrowding of parking lots (on and off-site)

With more vans, lorries and trucks then ever passing though estates, there is an inevitable increase in pressure on your warehouse parking requirements. This will make it harder for vans to reach loading bays at their appointed time. There may also be a rise in illegal parking off site – which risks disputes with the local community and fines from local authorities.

Disputes between drivers and fulfilment centre staff

Confusion about whose turn it is to approach delivery bays, perceptions that certain drivers or staff are taking too long and similar confusion may well result in friction and outright conflict between drivers and warehouse staff.

Breaking rules

A rise in traffic could see fulfilment centres unintentionally breaking rules around overcrowding, noise and pollution.

All these factors cause delays, waste time and mean logistics companies, warehouse businesses and individual drivers lose money. At the same time, customers will be frustrated – and are liable to shop elsewhere in future.

How can these kinds of delays be reduced?

Nwave’s smart parking technology makes your warehouse Covid-19 ready

Nwave’s smart parking sensors provide your operations with a simple and efficient method for understanding vehicle traffic through your estate and ease warehouse layout design problems. We have developed robust, best in class ground-based parking lot sensors that can detect if a space is currently occupied or not. This then feeds real time data into your yard management system which can help you better manage your existing parking space inventory for trucks and trailers.

Here’s how Nwave could help you adapt to the increase in demand for delivery vehicles:

- Our smart parking sensors are installed in spaces and loading bays around your estate, allowing you to implement a smart warehouse traffic plan

- Using Bluetooth, our sensors can specify which particular vehicle is occupying a parking space

- When vans and trucks park in those spaces, you can see, in real time, when they are occupied

- Using a mobile app, drivers can also see which spaces are free (you can also tell them where to park and when). If there are no spaces available, trucks and vans know not to enter your estate

- Vans and trucks will only use pre-defined parking spaces, which avoids congestion and confusion

- Using data from our vehicle detection sensors, warehouses can automatically optimise queueing, improve inbound and outbound logistics and reduce time losses by setting operational KPI’s

The coronavirus lockdown has created a huge rise in deliveries and a parallel rise in traffic at warehouses and fulfilment centres. And, with new consumer habits, we can only expect this increase in traffic to be sustained long term. To learn how our smart parking solutions can improve fleet management around your warehouses, contact Nwave today.